Nowadays, heating is not only for urban residents in the north. There is also a large demand for heating in the south, vast rural areas or remote areas. Especially in the transition zone between the north and the south of my country, rural areas in the north, some office buildings and old communities where heating cannot be achieved, there is an urgent need for heating. The investment in the construction of large-scale centralized heating systems in the above-mentioned areas is too large, the cost is too high, and the feasibility is low. Therefore, the household heating method of graphene electric floor heating has become one of the heating solutions. While meeting the heating needs of users, it also complies with the national policy of energy conservation and environmental protection. In addition, graphene can also release far-infrared light waves with the same frequency as the human body, which is of great benefit to residents and has the effects of green environmental protection and health preservation. If you want to install graphene electric floor heating in your home, you might as well learn about it first.

What is graphene electric floor heating

Graphene electric floor heating is an electric floor heating made of graphene. Graphene is a new material. This material itself has the function of powering on. After the development of science and technology, it has been transformed into electric floor heating. As long as it is powered on, it can quickly heat up and generate heat.

Advantages of graphene electric floor heating

01

Environmental protection

The graphene floor heating system directly uses electricity as energy and electric heating film as heating element, directly converting electrical energy into thermal energy, avoiding the pollution of urban atmosphere by harmful gases such as carbon dioxide and sulfur dioxide emitted during the combustion of coal for heating.

02

Energy saving

1. Building energy saving. The graphene floor heating system requires that the residence must meet the national energy-saving building standards before it can be installed, which is saving on top of saving, 2. Product energy saving. The electric heat conversion rate of the graphene floor heating system exceeds 90%, and compared with the water floor heating with serious heat loss, it consumes less energy, 3. Behavior energy saving. With the graphene floor heating system, heating can be controlled by time and room, and energy saving is more thorough.

03

Save money

1. Save land and money. There is no need to build a boiler room, lay a pipeline network, store coal, pile ash, etc., which saves land, there is no need for traditional indoor terminal equipment, which saves the area occupied by indoor radiators and indoor boilers.

2. Save money in use. The graphene floor heating system is an energy-saving system that can be turned on and off at will and adjusted at any time. Saving energy means saving money.

04

Safety

1. Self-safety. The electric heating film is a special waterproof and insulating design. It is insulated and waterproof. It can be used normally in a humid environment or even in water (constant temperature swimming pool). It is extremely safe.

2. It eliminates safety hazards. Traditional building heating is prone to safety accidents such as leakage, bubbling, dripping, and large-scale heating interruption due to aging pipe networks, which increases instability factors. With the graphene floor heating system, as long as the power supply is normal, the heating will not be affected.

Principle of graphene electric floor heating system

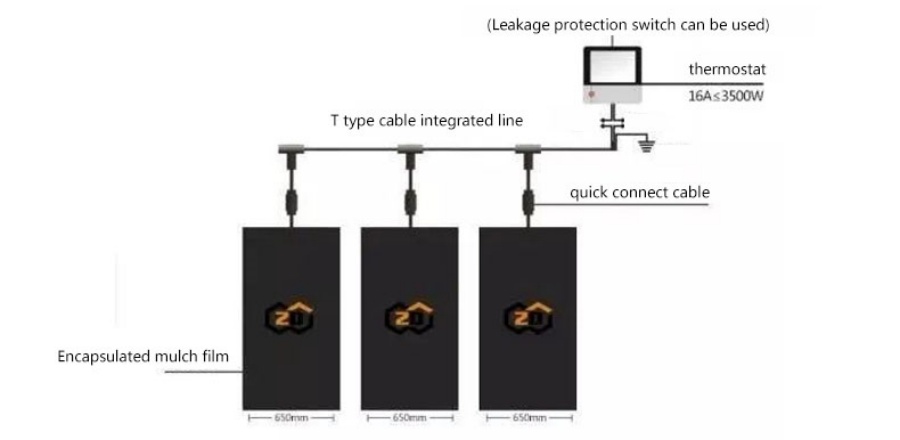

(Schematic diagram of laying graphene electric floor heating film)

First, let's take a look at the system schematic diagram of graphene electric floor heating. As shown in the figure below, we can see that the overall structure of the graphene electric floor heating system is simple, mainly composed of encapsulated floor film, quick connection cable, T-type cable integrated line, thermostat, and leakage protection switch.

Graphene electric floor heating design

The biggest advantage of graphene electric heating is that it can control the temperature in different areas. According to the floor, orientation, and insulation conditions of the house, there will be senior and experienced designers to design the laying area and power of the graphene electric heating film for you.

(Graphene electric floor heating design for a homestay)

Graphene electric floor heating construction

01

Keep the ground flat

Before construction, the ground must be thoroughly cleaned to ensure that there are no debris or protruding objects on the ground, and the horizontal drop of the floor tiles is less than 1cm, which meets the requirements of flat paving.

02

Paste the boundary insulation strip layer

Paste the floor heating boundary insulation strips (about 1cm thick and 5cm high) around the room to prevent heat from dissipating along the cement layer to the wall. The ends of the floor heating insulation strips should be connected and connected with tape at the joints.

03

Laying the insulation layer

Extruded board (a kind of insulation material) should be cut neatly, and the gap between the boards should be less than 5mm. Use tape to seal the gap between the boards. The surface of the extruded board is flat. It is strictly forbidden to assemble a large number of small pieces. The thickness of the extruded board is 20mm. If it is a ground layer, the thickness of the extruded board is increased to 30mm. There is a 3-5mm expansion joint between the extruded board and the wall.

Laying the insulation layer can well retain the temperature of the graphene electric heating film, prevent heat from transferring downward, and reduce the ineffective heat loss of the structural layer. Note: Poor quality insulation materials will cause serious heat loss and seriously increase heating energy consumption.

04

Laying the reflective film

The role of the reflective film in floor heating is mainly to prevent heat from dissipating from the ground, thereby effectively improving the heat reflection and radiation capacity and ensuring the constant indoor temperature. When laying the reflective film, keep the reflective film more than 20cm away from the wall, and use tape to connect the reflective film where it meets.

05

Laying graphene electric heating film

Before laying, first check whether the heating film packaging is damaged and whether the appearance is intact. If there is any damage or other abnormalities, the heating film needs to be replaced. When laying, it should be arranged according to the design drawings. The graphene electric heating film should be placed neatly, and the length, position and spacing between them should be accurate. Use tape to fix the electric heating film to ensure that the electric heating film and the insulation board are tightly attached (when designing the drawings, the floor heating film should be kept at a distance of more than 20cm from the wall). After laying, the appearance needs to be inspected to observe whether the construction has caused any damage.

06

T-type cable connection

(1) Connect the cables according to the design and installation drawings. The actual T-type cable should be consistent with the design drawings. When installing, push the male and female connectors to the bottom, check whether the silicone gasket is missing, and then tighten the cap.

(2) After the connection is completed, the cables are fixed to the extruded board with tape.

(3) To enhance waterproofing, waterproof tape can be used to wrap the connector and T-type connector. When connecting the connecting wire to the thermostat, pay attention to the distinction between the neutral wire and the live wire (the blue wire is the neutral wire and the brown wire is the live wire). The T-type cable can be spliced, and the end of the cable can be sealed with a main line plug.

(4) If there are obstacles on the ground during the laying process, the branch line can be sealed with a branch plug.

07

Install the high temperature protection line

Take the high temperature protection line, connect one end to the thermostat according to the length of the line (3m), and place the other end on the floor heating film. The temperature control probe is fixed to the middle part of the floor heating film with tape.

08

On-site inspection

Install the thermostat, use an infrared thermometer to detect the temperature of the electric heating film after powering on, judge whether the electric heating film is working normally according to the environmental conditions, and observe whether each piece is evenly heated. If poor heating occurs, check whether the connection plug is loose.

When the power is off, use a megohmmeter to detect the insulation resistance of the electric heating film. The megohmmeter reading should be greater than 5MΩ. If it is less than 5MΩ, it means that the electric heating film or the circuit may be damaged.

09

Laying cement cushion

Configure cement according to the standard, and the water content of cement should not be too high. Do not pierce the PVC film and electric heating film during paving. If the electric heating film is pierced, the electric heating film should be replaced. The laying thickness is about 2-3cm, and the cement cushion should be flat to facilitate the laying of the upper decorative layer.

10

Laying the decorative layer

Lay tiles or wooden floors according to different decorative styles.

Use of graphene electric floor heating

01

Choose a comfortable temperature

When using an electric heating film heating system, temperature and cost are closely related. Choosing the right temperature and heating time is very important for saving costs. The most comfortable temperature for the human body is generally around 20 degrees Celsius, but some people are used to higher temperatures. Every degree of temperature increase will increase energy consumption by 5%, and the indoor temperature is too high, resulting in a large temperature difference between indoor and outdoor, which is more likely to cause colds and other diseases.

02

Correct use of the heating system

Once the floor heating system is turned on, try not to turn off the system during the heating period. Users can set the temperature as needed through the smart thermostat according to their living and working hours, which is conducive to saving energy. Frequent opening and closing of the thermostat will cause the electric heating film to frequently change its working state, which will not only cause poor heating effect, but also greatly increase heating costs, which is counterproductive.

▪ Try to reduce the number of times doors and windows are opened, and try to arrange ventilation at noon when the sun is bright to avoid heat loss.

▪ The thermostat is a precision electronic component. Do not disassemble or shake it at will to avoid damage to the thermostat.

▪ It is strictly forbidden to cover objects in the heating area of the electric heating film to ensure that the heat is fully dissipated.

▪ It is forbidden to drill holes, nail, or otherwise damage the electric heating film in the electric heating film laying area.

Precautions

01 Newly installed graphene floor heating requires special attention. The cement mortar layer needs to be naturally air-dried for at least 21 days. Do not turn it on even if it is cold during this period to prevent the graphene floor heating circuit from short-circuiting. It should be noted that the first time it is turned on, due to the presence of moisture in the cement layer and the wall, the power consumption is large when reaching the set temperature, and the power consumption returns to normal after use.

02 In addition, it is forbidden to hit, drill, nail, drill, etc. on the ground with graphene. If it is really necessary, it is necessary to communicate with the graphene floor heating construction unit and carry out the construction under its guidance.